Description

Introduction

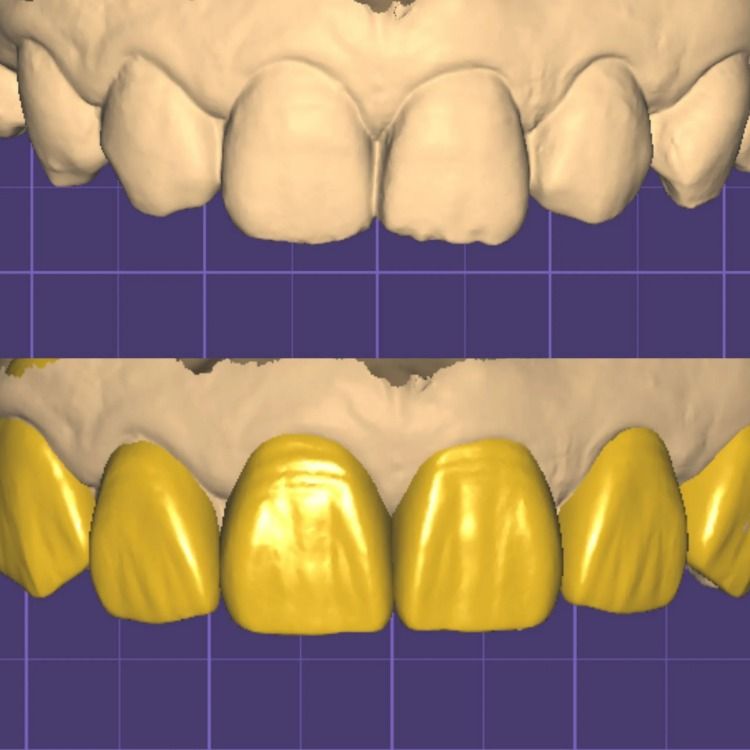

Preparing Exocad Designs for Manufacturing is an essential course for dental professionals and technicians who want to enhance their skills in preparing digital dental designs for production using 3D printing and milling technologies. This course delves into the necessary steps and best practices to ensure that Exocad designs are optimized for manufacturing, allowing for precise, high-quality dental restorations such as crowns, bridges, and dentures. Through a combination of theory and practical tips, participants will learn to troubleshoot common design errors, optimize files for different materials, and ensure that the designs fit manufacturing requirements.

Prerequisites of Exocad Designs for Manufacturing

Participants should have the following prerequisites:

- Basic knowledge of Exocad and its core design tools.

- Familiarity with digital dentistry, including CAD systems and their applications in dental restoration.

- Understanding of dental anatomy and restoration processes.

- Experience with 3D printing and/or milling technologies in dental applications.

- Access to Exocad software and 3D printing or milling equipment for hands-on experience.

Table of Contents

- Introduction to Digital Manufacturing in Dentistry

1.1 Overview of 3D Printing and Milling Technologies

1.2 Role of Digital Manufacturing in Dentistry

1.3 Benefits of Preparing Exocad Designs for Manufacturing

1.4 Overview of Materials Used in 3D Printing and Milling - Design Optimization for Manufacturing

2.1 Optimizing Geometry and Wall Thickness

2.2 Ensuring Proper Fit and Function in Restorations

2.3 Adjusting Designs for Different Materials

2.4 Balancing Aesthetic and Structural Considerations - File Preparation for 3D Printing

3.1 Exporting STL Files from Exocad for Printing(Ref: Mastering Exocad for Complex Restorations)

3.2 Preparing Files for Resin and Metal Printing

3.3 Slicing and Layering Considerations for 3D Printing

3.4 Post-Processing Techniques for 3D Printed Models - File Preparation for Milling

4.1 Exporting Files for Milling (STL, AMF, etc.)

4.2 Selecting the Right Milling Machine for Your Design

4.3 Designing for Wet vs. Dry Milling

4.4 Best Practices for Milling Ceramic, Resin, and Metal Materials

4.5 Post-Milling Adjustments for Final Fit - Troubleshooting Common Design Issues

5.1 Identifying Common Design Errors in CAD Files

5.2 Ensuring Proper Marginal Fit and Occlusion

5.3 Adjusting Design Features for Milling and Printing Compatibility

5.4 Ensuring Precision in Final Restorations - Material Selection for 3D Printing and Milling

6.1 Understanding Material Properties and Their Impact on Design

6.2 Selecting Materials for Functional and Aesthetic Considerations

6.3 Working with Resin, Ceramic, and Metal Materials

6.4 Material-Specific Considerations for Fit and Durability - Integrating Exocad with CAD/CAM Systems

7.1 Overview of CAD/CAM Workflow Integration

7.2 Linking Exocad to 3D Printers and Milling Machines

7.3 File Compatibility and Export Options (STL, AMF, etc.)

7.4 Best Practices for Synchronizing Design with Manufacturing Equipment - Quality Control and Precision in Manufacturing

8.1 Verifying Design Accuracy Before Production

8.2 Ensuring Fit and Function Post-Manufacturing

8.3 Addressing Common Manufacturing Challenges

8.4 Post-Manufacturing Checks for Final Restoration Quality - Case Studies and Practical Applications

9.1 Real-World Examples of Exocad Designs Prepared for Manufacturing

9.2 Case Study 1: Full-Arch Restoration Design for Milling

9.3 Case Study 2: Custom Implant Abutment Design for 3D Printing

9.4 Addressing Design Challenges in Complex Restorations - Conclusion and Next Steps of Exocad Designs for Manufacturing

10.1 Key Takeaways from Preparing Exocad Designs for Manufacturing

10.2 Implementing Best Practices in Your Workflow

10.3 Further Learning and Resources

Conclusion

Upon completing this course, participants will be equipped with the knowledge and skills needed to prepare their Exocad designs for a smooth transition into 3D printing and milling production. By mastering design optimization, file preparation, material selection, and troubleshooting, participants will ensure that their digital restorations are accurately fabricated, meet clinical requirements, and enhance overall treatment outcomes. This expertise will help dental professionals streamline their workflows, reduce manufacturing errors, and deliver high-quality restorations that exceed patient expectations.

Reviews

There are no reviews yet.