Description

Introduction

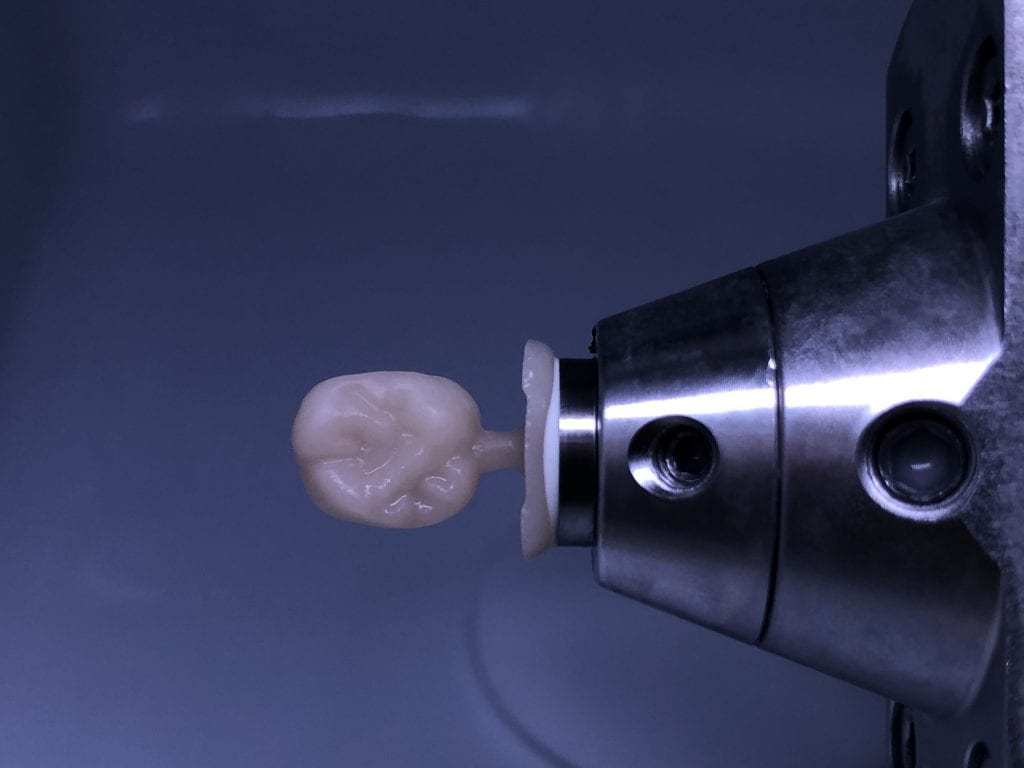

3D Printing and Milling Integration in Exocad is a specialized course that focuses on how dental professionals can seamlessly integrate 3D printing and milling technologies with Exocad software. This course covers the workflows, processes, and tools required to design and manufacture dental restorations and appliances using both digital fabrication methods. By combining Exocad’s advanced CAD capabilities with state-of-the-art 3D printing and milling technologies, participants will learn how to produce high-quality, precise dental solutions that streamline the restoration process, enhance clinical outcomes, and improve patient satisfaction.

Prerequisites of 3D Printer Integration Exocad

To get the most out of this course, participants should have:

- A basic understanding of digital dentistry and CAD software.

- Familiarity with Exocad and its core functionalities.

- Experience in dental restoration techniques, including crowns, bridges, and dentures.

- Knowledge of 3D printing and milling technologies in dental applications (basic understanding).

- Access to Exocad software and a 3D printer or milling machine for hands-on exercises.

Table of Contents

- Introduction to 3D Printing and Milling in Dentistry

1.1 Overview of 3D Printing and Milling Technologies

1.2 Benefits of Digital Fabrication for Dental Restorations

1.3 The Role of Exocad in Integrating Digital Fabrication Methods

1.4 Overview of 3D Printing and Milling Materials in Dentistry - Setting Up Exocad for Digital Fabrication of 3D Printer Integration Exocad

2.1 Configuring Exocad for 3D Printing and Milling Workflows (Ref: Getting Started with Exocad for Dental Professionals)

2.2 Integrating Exocad with 3D Printers and Milling Machines

2.3 Understanding File Formats and Compatibility (STL, AMF, etc.)

2.4 Preparing Your Exocad Designs for Fabrication - Designing for 3D Printing and Milling

3.1 Designing Restorations for 3D Printing: Key Considerations

3.2 Best Practices for Designing Restorations for Milling

3.3 Incorporating Material Properties into Design Decisions

3.4 Ensuring Fit and Function in Printed and Milled Restorations - Workflow for 3D Printing in Exocad

4.1 Preparing and Optimizing Designs for 3D Printing

4.2 Slicing and Layering for Optimal Results

4.3 Choosing the Right 3D Printer for Dental Restorations

4.4 Post-Processing and Finishing Printed Models - Workflow for Milling in Exocad

5.1 Preparing and Optimizing Designs for Milling

5.2 Milling Techniques: Wet vs. Dry Milling

5.3 Selecting the Right Milling Machine and Tools

5.4 Post-Processing Milled Restorations for Final Fit - Troubleshooting and Quality Control

6.1 Common Issues in 3D Printing and Milling Workflows

6.2 Ensuring Accuracy in Printed and Milled Models

6.3 Adjusting Designs for Better Fit and Function

6.4 Quality Control Measures: Verifying Dimensions and Specifications - Designing Complex Restorations with 3D Printing and Milling

7.1 Designing Bridges, Crowns, and Veneers for Digital Fabrication

7.2 Creating Custom Abutments and Implant Guides

7.3 Designing Dentures and Orthodontic Appliances Using 3D Printing and Milling

7.4 Integration of Multi-Unit Restorations in Exocad for Fabrication - Advanced Techniques and New Technologies

8.1 Hybrid Workflows: Combining 3D Printing and Milling for Optimal Results

8.2 Leveraging Advanced 3D Printing Materials for High-Quality Restorations

8.3 Integrating In-House and Outsourcing Fabrication Workflows

8.4 Exploring New Trends and Innovations in 3D Printing and Milling Technologies - Case Studies and Practical Applications

9.1 Real-World Case Studies of 3D Printing and Milling Integration

9.2 From Design to Fabrication: Step-by-Step Workflow for Specific Restorations

9.3 Analyzing Common Challenges and How to Overcome Them

9.4 Best Practices for Efficient and High-Quality Production - Review and Summary

10.1 Recap of Key Concepts in 3D Printing and Milling Integration

10.2 Review of Exocad’s Role in Digital Fabrication Workflows

10.3 Next Steps for Mastering Digital Fabrication in Your Practice

Conclusion

Upon completion of this course, participants will be equipped with the knowledge and skills needed to integrate 3D printing and milling technologies into their digital workflows with Exocad. They will understand how to design, optimize, and fabricate high-quality dental restorations using both digital fabrication methods. This integration will not only enhance the precision and efficiency of the restoration process but also improve the overall patient experience. With the tools and techniques learned, dental professionals will be ready to embrace the future of digital dentistry and deliver superior results.

Reviews

There are no reviews yet.